Facility Capabilities

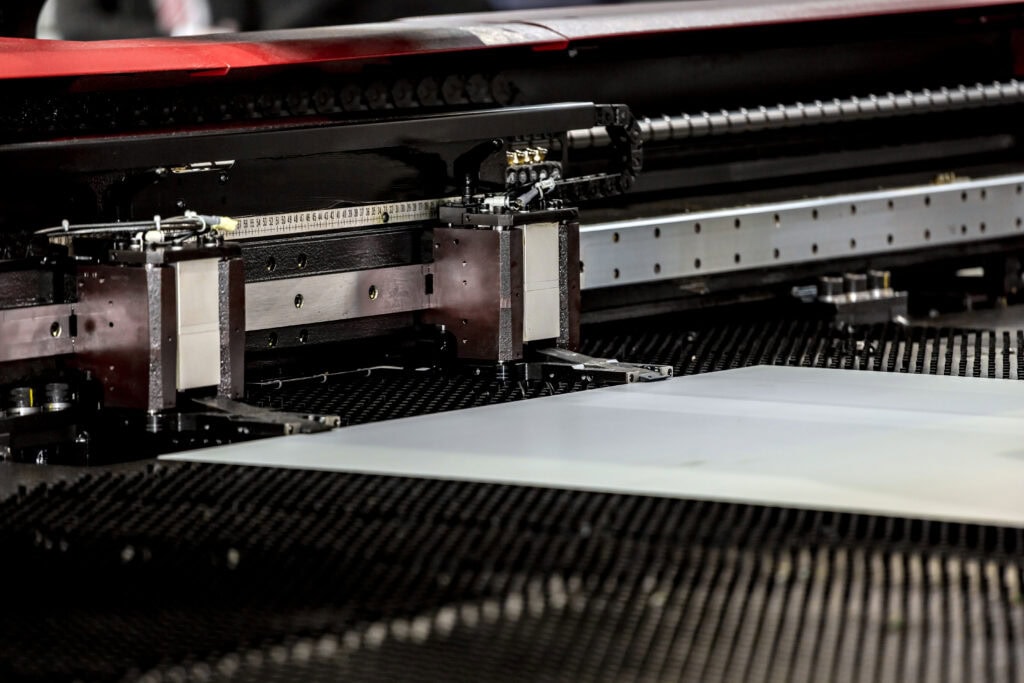

Fabrication Equipment

- Amada PEGA 344 – CNC, 56 station, turret punch press, 33 ton punching capacity

- Trumpf TruBend Series 2000 – 10′ bend capacity in mild steel and aluminum

- Tennsmith manual 8′ brake press

- Tennsmith manual 10′ brake press

- Tennsmith Model LM1014 – 10′ Mechanical Shear

- Shearing Capacity – 14ga mild steel – 16ga stainless steel

- Pemserter Series 4 Manual Insert Press

Machining Equipment

- Komo Extreme – CNC Machining/Routering Center, 5’x10′ capacity with 4th Axis (C Axis)

- Komo VR 510 Mach One S – CNC Machining/Routering Center, 5’x10′ capacity

- Leadwell MCV-760 AP-CNC Machining Center – Capacity: X: 29.92 Y: 20.00 Z: 20.00

- Bridgeport manual milling machine

- Wilton Model #VSG 20 heavy duty, high production drill press.

- Horizontal bar cutting saw

Panel Cutting/Processing Equipment

- Safety Speed Cut Vertical Panel Saw

- 10″ Table Saw – Delta Contractor’s Tilting Arbor Unisaw with Unifence

- 12″ Disc Sander – Wilton #4400A

- 10″ Radial Arm Saw – Delta Contractor’s Deluxe

- Delta Dust Collection System

- Pinch Rollers from Evans Machinery (2)

- Adhesive Spray System – Large Volume booth and tank.

- Custom Hot-Wire System for Cutting EPS Foam.

- KamWeld Strip Heaters – Used in line bending of thermoplastic sheet.

Technology

- AutoCAD/Router-CIM-software used for CNC machining and routering

- SMP/IS-CAD software used for sheet metal punching and forming

- Shop computer workstations using ECI E2 software for tracking orders from start to finish.

- Workstations are also used for the following:

- Quality Checklists

- Delivery Information

- Job Tracking

- Current Inventory

- Layouts

- BOMs

- Workstations are also used for the following:

Facility Management Equipment

- Hino Truck with 26′ long box

- 4 Forklifts

- Overhead Crane System with 2 ton hoist

- Air Compressor

- Shipping/Receiving Dock at trailer height.

- Overhead door with drive in and crane access.

Discover How We Can Meet Your Custom Specifications

Our dedicated staff can assist in creating lighter, stronger, more dependable, less expensive products.

Contact Us Request a Quote